What Are the Four Rules of Wrenches?

toukokuu 16, 2025

Understanding the fundamental rules can make a significant difference in both efficiency and safety. Whether you are a professional mechanic or a DIY enthusiast, knowing how to properly use tools like the 5nm torque wrench, 6 mm Allen wrench, and 5/16 Allen wrench can enhance your work quality and prolong the life of your tools. The four basic rules of the wrenches that every user must adhere to are what we will cover this article.

Rule 1: Choose the Right Wrench for the Job

No doubt, your choice of the right tool for a job is of paramount importance in order to get the best results.

Types of Wrenches

5nm Torque Wrench: This super accurate device is just right for lighter tasks where low torque is required. Sectors such as electronics and precision machinery get the most out of this tool. The 5nm torque wrench guarantees that the joining parts (in the form of bolts and nuts) will be properly tightened without any harm being caused to the sensitive parts.

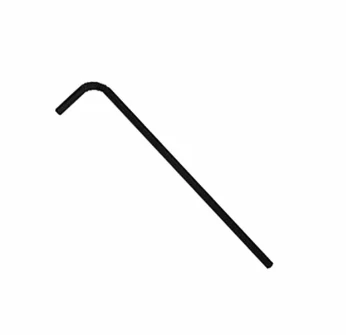

6 mm Allen Wrench: This L-shaped metric hex key is the most common and it is utilized in the driving of standard metric hex screws. Its configuration makes it suitable for precise torque control, so the tool is indispensable in the course of assembly in machines and electronics.

5/16 Allen Wrench: The wrench is a favorite tool in North America and is a fit among hexagonal screws and bolts having their size 5/16 in. It is an excellent choice for assembling furniture and bike maintenance as well.

Rule 2: Use the Correct Technique

Being very careful while applying torque is one of the key factors in obtaining good results. Here are some tips on the correct usage of the wrench:

Hold the Wrench in a Proper Way: Be sure you have a tight hold on the wrench. This will prevent it from slipping and will allow you to have better control. For L-shaped wrenches such as the 6 mm and 5/16 Allen wrenches, you can use the short arm to control the torque and the long arm for fast rotation.

Exert Constant Force: When using a 5nm torque wrench, consistency is the key to the attainment of a particular torque value.

Adhere to the Manufacturer’s Specifications: Furbish up the torque specs given by the manufacturer. That way, you apply the right amount of force, over-loosen the components.

Rule 3: Regular Calibration and Maintenance

To secure the continual fitness and accuracy of your wrenches, you got to have them calibrated frequently and do a regular check-up.

Necessity of Calibration

5nm Torque Wrench: This is a type of wrench that requires being well calibrated to maintain its accuracy levels. Checking its calibration regularly is a good idea. This will mean you are aware whether it has gone outside the allowable error of ±3% to ±5%.

Maintenance: Ensure you frequently clean and clear the wrenches and also provide the necessary precautions of isolation from dirt. Store it in a case to shield it from destruction.

Keep your tools in good condition so that they can serve you well on all your projects.

Rule 4: Understand the Limits of Your Wrench

Each wrench is made to withstand a certain degree of load after which it can weaken and eventually fail.

Finding Out the Maximum and the Minimum Torque

5nm Torque Wrench: This wrench is adjustable only up to a low level of force. That is why if you want to achieve larger torques, you should not use it.

Hex Wrenches: The metrics 6mm Allen wrench as well as the 5/16 Allen wrench has a specific torque range wherein they can effectively work. Always remember to be inside these limits for you to screw and unscrew well without breaking the wrench.

Avoid Overloading

Overloading wrenches can lead to inaccurate torque application and tool failure. Always use the right size and type of wrench for the job to prevent accidents and ensure the safety of your work.

Päätelmä

Keeper knowing and practicing the four rules of the wrenches, you are bound to significantly increase your productivity and optimize your work while at the same time ensuring workplace safety. This includes selecting the most suitable wrench, mastering the best practices, taking good care of your tools, and fully understanding their features and limitations.

YDS Tool is a one-stop-shop for all your hand tool needs. We take pride in the quality of our products. Ota yhteyttä today to get detailed information on our products and services!